Blog

-

Read more »

When it comes to enhancing the exterior of your home, few things make as big of an impact as the choice of render colour.

Selecting the right render colour scheme can elevate your home's curb appeal and express your personal style, but which colour scheme to choose?

-

Posted: November 15, 2023Read more »

Explore the diverse cladding options for your granny flat, including Blueboard Fibre Cement Sheets, Brick Veneer, Poly Panels with Acrylic Render, and AAC panels. Learn about the benefits and considerations of each material to make an informed decision that meets your project's needs and budget.

-

Read more »

So you've decided to paint over existing render on your home's facade?

Here we discuss the benefits of painting render, types of paint to consider and tips on how to apply it.

-

Posted: June 17, 2022Read more »

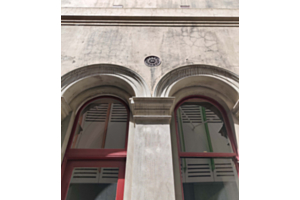

Exterior architectural mouldings have been around long before us. They symbolise craftsmanship and pride.

These are our top 5 reasons to use exterior mouldings on your home to make it the best in the neighbourhood!

-

Posted: February 24, 2022Read more »

If you are in the market for cladding options, you may have heard the term 'autoclaved aerated concrete' (AAC).

You may be wondering what AAC panels are and why you should select this type of cladding for your project? Learn why AAC panels are a popular choice for modern construction projects.

-

Read more »

Exterior wall cladding offers protection from harsh weather conditions, as well as providing insulation, noise control and energy efficiency, and enhancing the look of a facade.

Here we describe the various types of cladding that can be used as standalone or finished with render/texture and other decorative coatings.